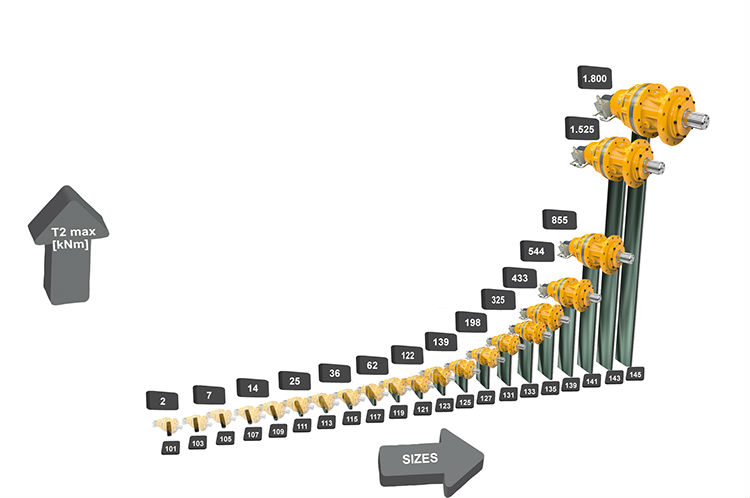

PLANETARY GEARBOXES

Brevini has a complete range of modular design planetary gearboxes for industrial applications. It combines high performance with low cost and compact size, excellent reliability, simple installation and reduced maintenance. Brevini’s industrial planetary gearboxes come in a range of sizes to ensure optimum duration and silent running in all sorts of applications.

Dinamic Oils planetary gearboxes have a design that ensures high performance in compact dimensions, they are suitable for a wide range of applications including mobile machines, drilling, marine, mining and industrial machinery. Countless customized solutions make this gearbox range adaptable to any kind of application where compact and reliable mechanical transmission is needed.

Reggiana Riduttori is dedicated to the production of planetary gears and wheel gears which are entirely made in Italy. Products are manufactured with top quality raw material. The assembly and storing phases are strongly influenced by a high innovation level which is guaranteed thanks to constant investments in research and development.

PLANETARY GEARBOX FEATURES:

– Up to 1.850.000 Nm

– Shortest delivery among competitors

WHAT ARE THE ADVANTAGES OF THE PLANETARY GEAR UNIT?

WEIGHT

A planetary gearbox weighs about 2/3 less than a correspondingly rated traditional gear unit, which means that supporting structures can be made lighter, and maintenance is made easier in the event that the unit needs to be removed.

DIMENSIONS

The planetary gearbox is significantly more compact, and therefore easier to install, than traditional units (worm, coaxial, parallel/right angle shafts).

COST

Thanks to high volume production of planetary trains, substantial economies of scale are obtainable, with the result that prices are highly competitive when compared to those of correspondingly rated traditional gear units.

HIGH TORQUE

The planetary gear train is characterized by multiple points of meshing contact, and with loads spread across at least three planet gears, high torques can be transmitted even with a unit of relatively compact dimensions.

REVERSIBILITY

Planetary gearboxes function in the same way and deliver the same performance in both directions of rotation. This is a notable advantage in the case of machines that alternate regularly between clockwise and anticlockwise rotation.

HIGH TRANSMISSION RATIOS

Using standard planetary reduction stages, units with transmission ratios of up to 3000 can be supplied.

LOWER INERTIA OF ROTATING PARTS

LOWER SENSIBILITY AGAINST SHOCKS

This is due to to higher design rigidity since there are shorter axis and internal gear force compensation

L10 LIFE ACHIEVED ONLY BY SATELLITE BEARINGS

External loads on reducer shafts do not influence L10 life of gear supporting bearings

REDUCE EXPENSES FOR MOUNTING

No expensive basement are request for planetary reducers as it is possible to mount them directly to the machine structure

MAINTENANCE WITHOUT SPECIAL TOOLS

Listed here all our gearboxes, universal shafts, gears and couplings.